Home Cuppa Convos Technical Snapshots Technical Snapshot: Screed Strengths – Traditional & Engineered

Technical Snapshot

Issue: Screed Strengths – Traditional & Engineered

Traditional screed consists of a mixture of sand and cement and is used in a wide variety of different projects. Traditional screed has a typical setting time of 24-48 hours, and a typical drying time of around 7 days per cm to fully cure.

Engineered screeds have increased flexural strength, enhancing their resistance to cracking, especially when applied on substrates of subpar quality or subjected to significant movement.

Concrete has a rugged, rougher appearance due to the coarse aggregates involved.

Screed, in contrast, possesses a smoother, more refined surface, partly because it employs finer aggregates.

It is important to have the correct MPA for a screed. Excessive cement content in a screed can lead to the deterioration of its structural integrity, resulting in potential crumbling.

As a rule, the mechanical strength of a screed suitable for installing any type of flooring for domestic use must be a minimum of

20 MPa, while for industrial use it must be a minimum 30 MPa.

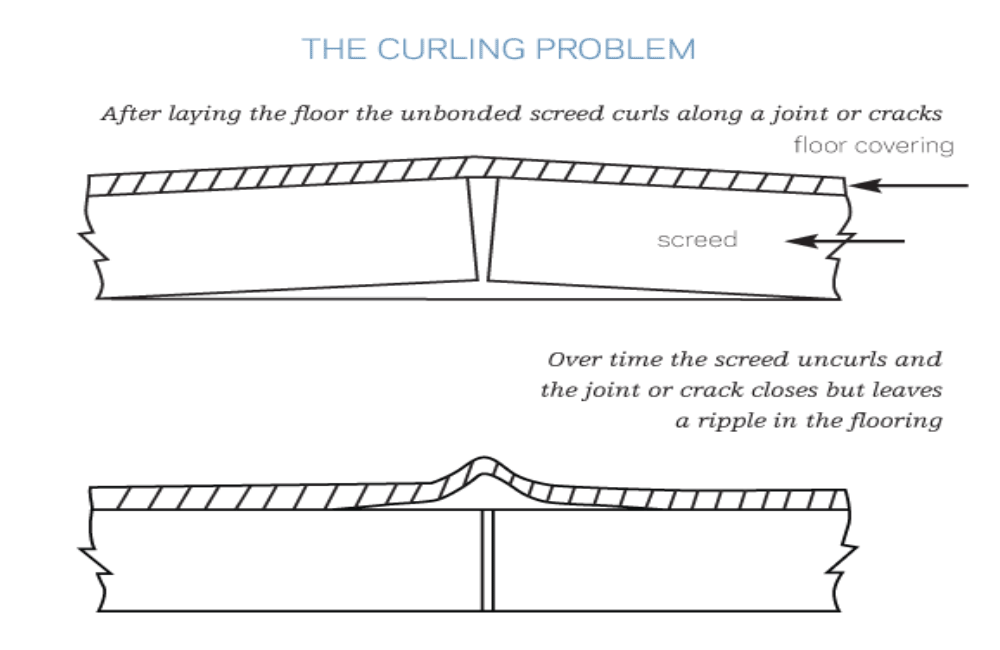

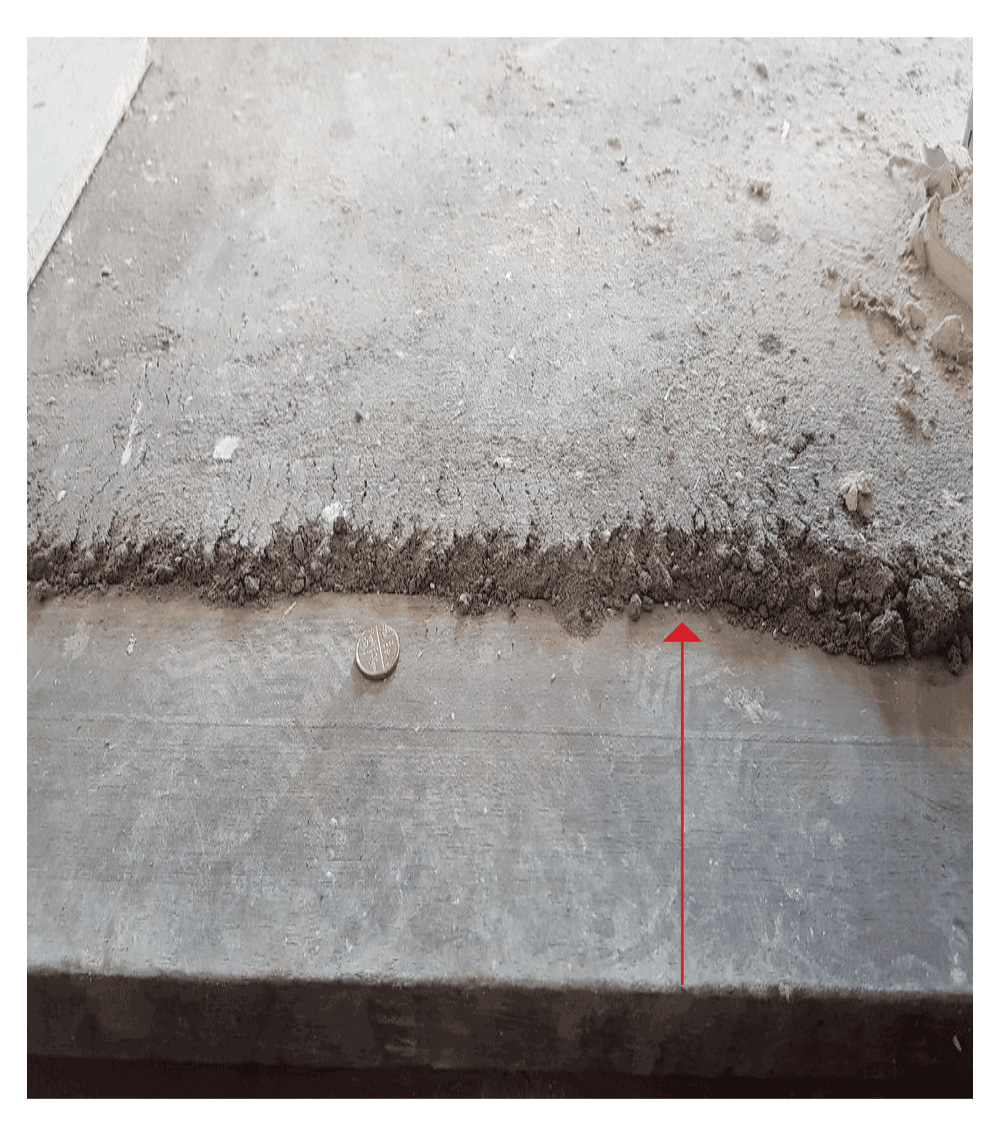

Another issue faced is curling and or cracking in a screed. This is due to being too thin, and unbonded to the substrate.

Incorrect

Crumbly Screed, incorrect MPA.

Solution

Using a screed with the correct consistency and applying the desired thickness, followed by an appropriate straight-edge tool to obtain a better surface finish are elements that will work together to give a successful outcome.

Correct

Take note of the thickness and consistency of the screed

Screed to drainage flange is ready for waterproofing