Home Cuppa Convos Technical Snapshots Technical Snapshot: Moisture Cured Polyurethanes

Technical Snapshot

Issue: Moisture Cured Polyurethanes

Solvent-based, moisture-cured polyurethane heavy-duty flooring and waterproofing systems require surface evaluation, accurate system selection, and professional installation to prevent expensive problems.

Taking time and effort to understand the potential issues and implementing the correct measures to prevent them is the hallmark of a successful professional applicator.

Bubbles, outgassing, bond failure at Substrate, and debonding in the form of a blister are some of the common issues experienced in application.

Air entrainment or bubbles may appear as small as a pinhead or greater. They may appear throughout the entire coating or in clusters. They are caused by air entrainment in the membrane during mixing and/or application, excessive heat outgassing is air pockets in porous substrates escaping during the curing process.

These pockets are then trapped in the coating, creating bubbles or pinholes. When the air above the substrate is warmer than the substrate temperature and the humidity is lower, the air trapped in the pores of the substrate expands and the air moves out of the substrate creating bubbles or pinholes, and these bubbles pop.

Debonding in the form of a blister is moisture vapour transmission that will cause loss of adhesion and blistering. The moisture in the porous substrate will migrate towards the warm, dry air above the substrate.

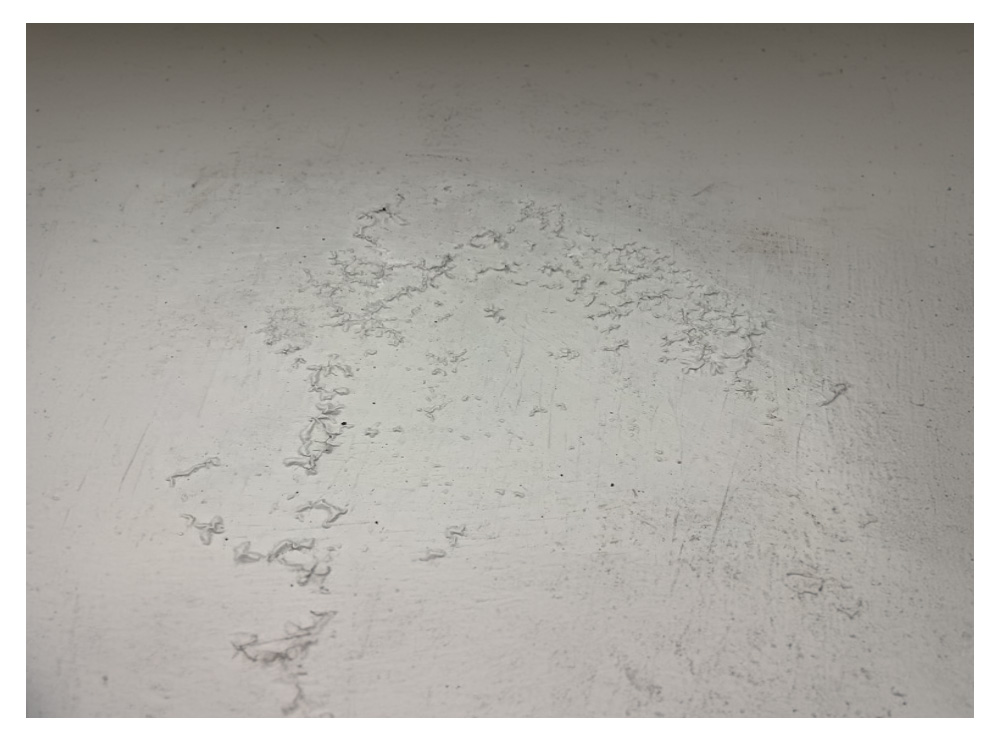

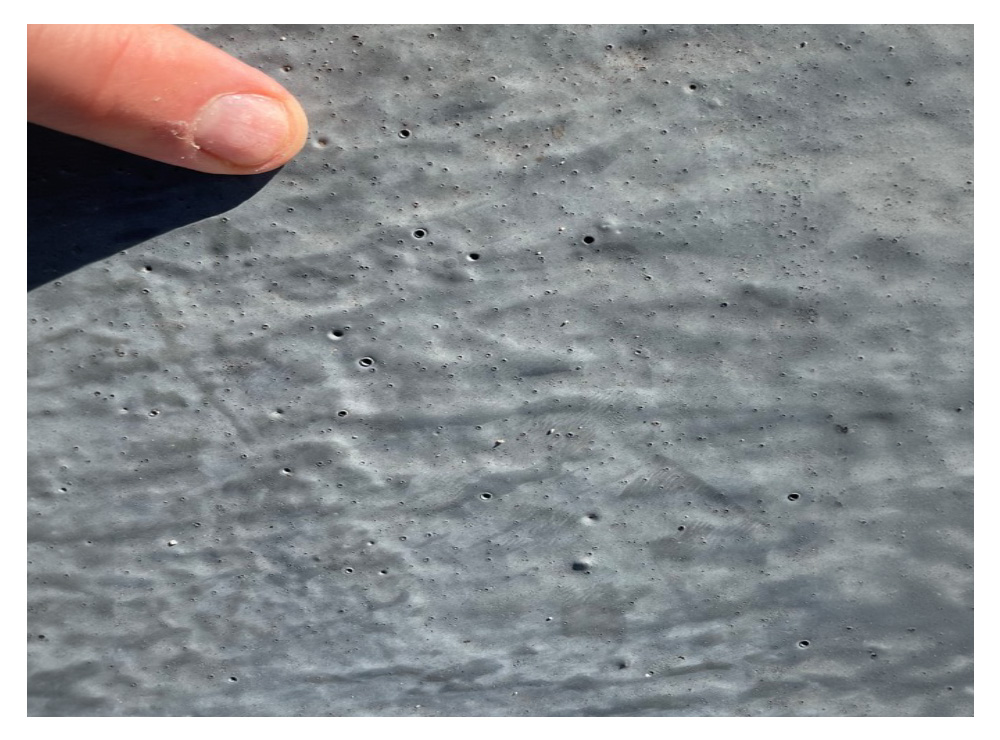

Incorrect

Pic 2. Outgassing caused by air pockets in porous substrates

Pic 3. Bond failure at the substrate from debonding in the form of blisters

Solution

Prevention of Bubbles

Use the manufacturer’s recommended equipment for mixing and application. Try to avoid excessive heat or elevated temperatures.

Monitor the environmental conditions, air, substrate temperature, dew point and humidity. Try to apply the first coat during the afternoon, when the substrate is cooling.

Prevention of Outgassing

This is done by checking the temperature and humidity conditions of the air and substrate.

When the temperature is rising, do not apply the membrane. Wait to apply materials when the temperature is falling. The use of an epoxy primer will serve better to seal off the trapped air in the substrate.

Prevention of Bond Failure at Substrate and Debonding in the form of Blisters

Blisters can be avoided by removing all contaminants such as concrete laitance, existing coatings, hardeners, sealers, and curing compounds that can interfere with adhesion and develop a surface profile suitable for the type of membrane being applied to promote mechanical adhesion.

Correct

Pic 5. The membrane is applied at the correct thickness, preventing pinholes

Pic 6. Always read the data sheet for the correct application