Home Cuppa Convos Technical Snapshots Technical Snapshot: Curing Of Substrate Prior To Membrane Application

Technical Snapshot

Issue: Curing of Substrate Prior to Membrane Application

Waterproofing issues continue to occur due to increased program pressure during construction to install membranes onto substrates not adequately cured.

All suppliers typically specify 28 days for curing to occur prior to any membrane application.

Curing rates to achieve the correct moisture content in a substrate prior to the membrane application is the key to correct adhesion and avoiding blistering and delamination issues.

Early application of membranes onto substrates with a high moisture content is the cause of most blistering and delamination issues.

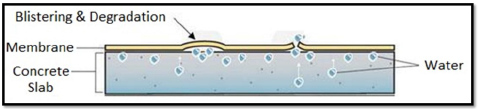

Entrapped moisture heats up and expands, trying to escape, it delaminates and blisters the membrane from underneath. Eventually, the blisters break resulting in water ingress.

AS 4564.2 -2012 outlines that “moisture content of mortar toppings and concrete substrates should have 8% or less, or suitable for the application of a membrane. The high moisture content of the substrate may cause blistering in some membranes and failure of the membrane system to fully cure.”

1. Blistering of the membrane due to entrapped moisture

2. Delamination of membrane from substrate

3. Delamination of membrane, high moisture content

Recommended Curing Times:*

- Concrete – 28 days curing.

- Hobs (100mm wide) – 14 days curing.

- Screeds (50mm or less) – 7 to 10 days curing.

- Block walls – 7 to 10 days curing.

- Roof plinths (10M2 or less) – 7 to 10 days curing.

*NOTE:

- Environmental factors play a huge part in construction – Curing times will vary depending on the season, summer vs winter, rainfall, and high humidity. Please speak to your Bayset representative to determine a fit-for-purpose solution on-site.

- 2-part spray applied polyurea requires the moisture content in the substrate to be 5% or less prior to application.