Systems

Wet Areas

Home Bayset Systems Wet Area Systems Frameless Showers Frameless Showers (Over Screed) – 208

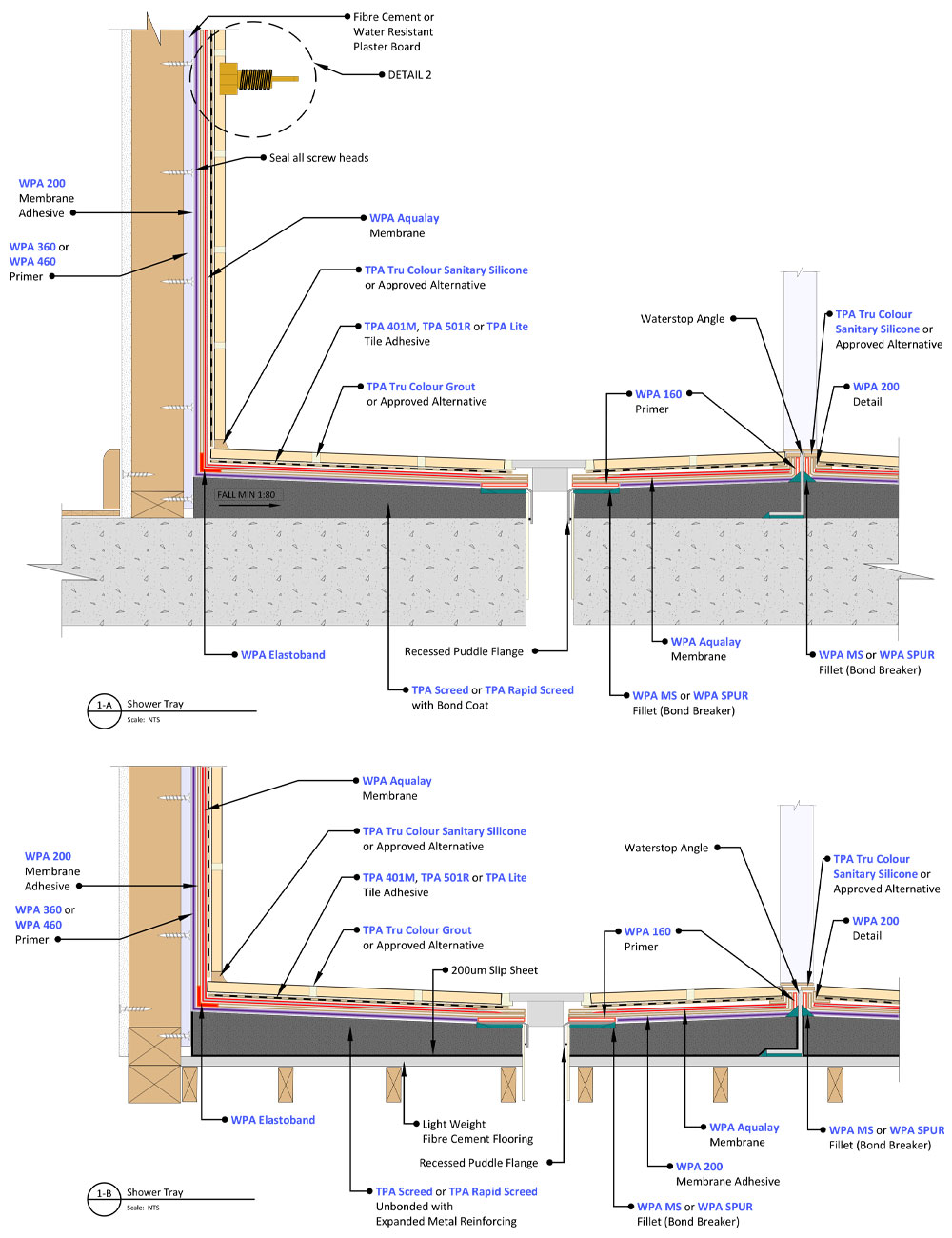

WP208 Waterproofing Wet Areas – Frameless Showers (Over Screed)

Preparation:

- All surfaces to be waterproofed must be firm, clean, dry, sound and smooth. All grease, oil, wax, curing compounds, loose material, paint and any other contaminants must be removed, masonry surfaces must be pointed flush and surface defects repaired. New concrete must be cured for a minimum of 28 days.

- External corners to be waterproofed must be bevelled to ensure a smooth transition of membrane from vertical to horizontal surfaces.

Installation:

- Waterproofing installation shall be in accordance with the applicable provisions of the National Construction Code.

Tile installation shall be in accordance with AS 3958 Installation of Ceramic and Stone Tiles.

- Install a waterstop angle to the perimeter of the shower and at the door opening.

- Install TPA Screed to achieve appropriate falls to waste. Where a bonded screed is required, apply a bond coat using TPA 401M or TPA Lite. Install TPA Rapid Screed for an engineered or rapid set screed, using a bond coat of TPA Rapid for bonded screeds.

TPA Screed is a pre-blended screed mixture for the installation of cementitious screeds and tile beds, suitable for internal and external floor applications.

TPA Rapid Screed is a pre-blended, rapid set, engineered screed mixture for the installation of cementitious screeds and tile beds, suitable for internal and external floor applications.

- Install a puddle flange to all waste pipes, ensuring that puddle flanges are recessed into the substrate.

- Install an appropriate fillet (bond breaker) along the waterstop angle where required using WPA MS or WPA SPUR.

WPA MS is a single-component, moisture-cured silane-modified hybrid sealant.

WPA SPUR is a high-quality, professional, universal, low-modulus sealant based on hybrid technology.

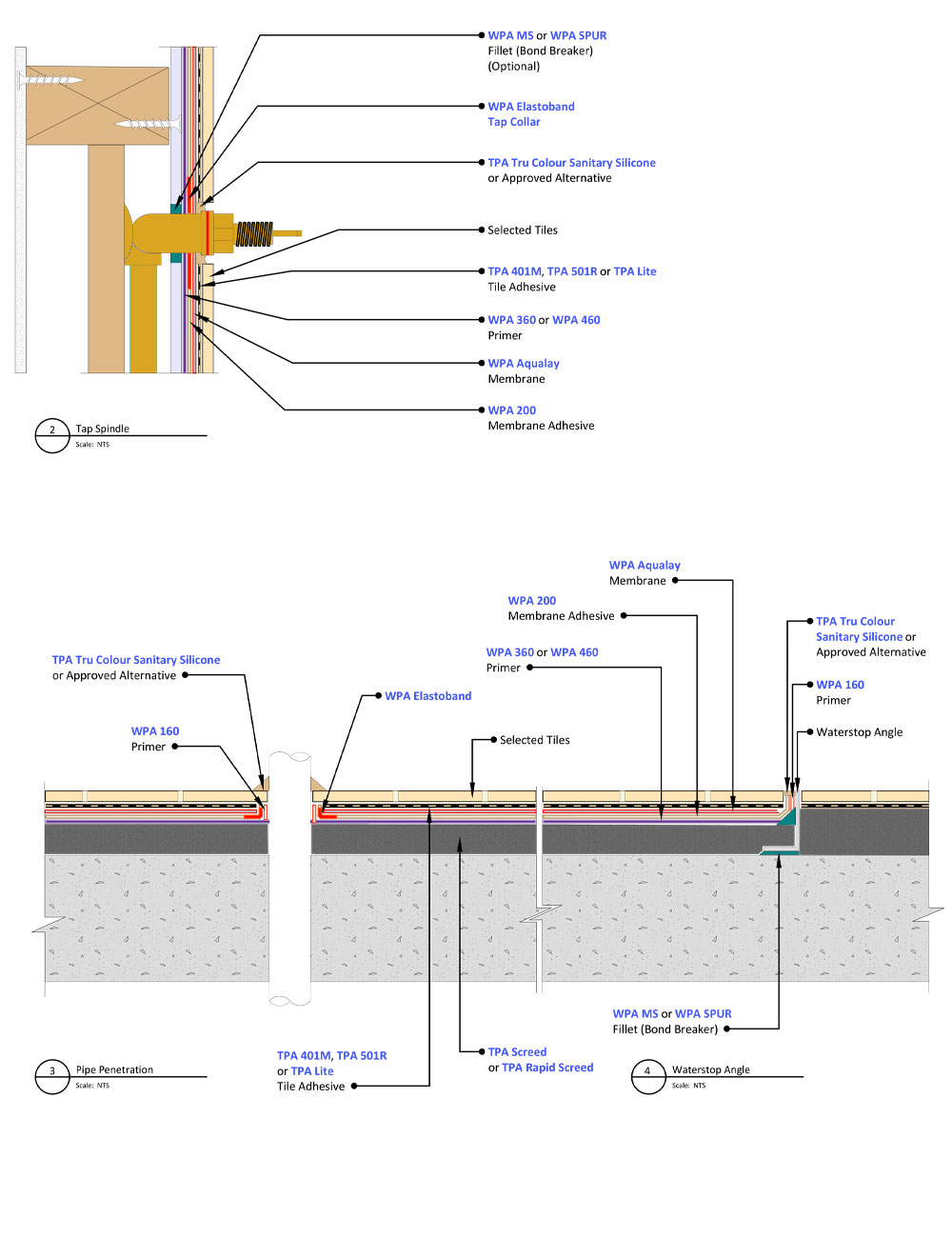

- Apply WPA 160 primer to non-porous surfaces, such as puddle flange and waterstop angle.

WPA 160 is a specialised solvent-free primer designed for enhancing the adhesion of subsequent membranes, adhesives, toppings and decorative finishes over non-porous substrates.

- Apply WPA 360 or WPA 460 primer to the substrate to be waterproofed.

WPA 360 is a water-based, low-solid, fast-drying primer.

WPA 460 is a two-part, water-based epoxy primer, used to seal concrete and masonry surfaces.

- Measure and pre-cut the WPA Elastoband and WPA Aqualay to the desired lengths.

WPA Elastoband is an innovative detailing system designed for waterproofing and sealing all types of joints, junctions and transitions subjected to movement.

WPA Aqualay is an innovative, high-performance, flexible, easy-to-implement new-generation sheet waterproofing membrane system.

- Apply WPA 200 to all transitions, extending it 100mm on both sides of the junction. Embed the WPA Elastoband into a wet coat of WPA 200 with a brush or appropriate plastic trowel, ensuring fabric edges are fully wetted out, removing air pockets and excess WPA 200.

WPA 200 is a flexible, two-part, rapid-drying, cementitious waterproofing membrane system, specifically designed for use under tile, stone and exposed applications.

- Apply WPA 200 to the substrate ensuring 100% coverage. Position and embed WPA Aqualay into a wet coat of WPA 200 using a plastic trowel to remove all air pockets and excess WPA 200. All sheets must be overlapped a minimum of 50mm and sealed over with WPA 200.

- Pipe penetrations will require the WPA Aqualay to be cut to enable the sheet to be placed over the penetration. Measure and place a cut where the sheet will be positioned and install the sheet, ensuring the WPA Aqualay is firmly bonded around the penetration. Install WPA Elastoband into a wet coat of WPA 200 around the pipe penetration and complete the installation with a liberal coat of WPA 200 to fully seal the overlapped section.

- Install tiles using TPA 401M, TPA 501R or TPA Lite tile adhesive.

TPA 401M is a white, flexible, powdered adhesive for wall and floor applications.

TPA 501R is a cost-effective, high-coverage, flexible, powdered adhesive for wall and floor applications.

TPA Lite is a premium grade, white, fibre-reinforced, flexible cement-based tile adhesive, based on a lightweight formulation.

- Grout tiles using TPA Tru Colour Grout or an approved alternative.

TPA Tru Colour Grout is a high-performance stain & efflorescence-resistant grout, designed for use with most types of Ceramic, Mosaic, Natural Stone and Glass Tiles.

- Install backing rod to all perimeter and intermediate movement joints and seal with TPA Tru Colour Sanitary Silicone or approved alternative.

TPA Tru Colour Sanitary Silicone is a mould-resistant, non-diluted, high-performance, UV-resistant, neutral cure silicone sealant.

Products Used

- WPA MS

- WPA SPUR

- WPA 160

- WPA 360

- WPA 460

- WPA 200

- WPA Elastoband

- WPA Aqualay

- TPA Screed

- TPA Rapid Screed

- TPA Rapid

- TPA 401M

- TPA Lite

- TPA 501R

- TPA Tru Colour Grout

- TPA Tru Colour Silicone