Systems

Roofs

Home Bayset Systems Roofing Systems Exposed Concrete Waterproofing Concrete Roof – Exposed (Maintenance Trafficable) – 402

WP402 Waterproofing Concrete Roof – Exposed (Maintenance Trafficable)

Preparation:

- All surfaces to be waterproofed must be firm, clean, dry, sound and smooth. All grease, oil, wax, curing compounds, loose material, paint and any other contaminants must be removed, masonry surfaces must be pointed flush and surface defects repaired. New concrete must be cured for a minimum of 28 days.

- External corners to be waterproofed must be bevelled to ensure a smooth transition of membrane from vertical to horizontal surfaces.

Installation:

- Waterproofing installation shall be in accordance with the applicable provisions of the National Construction Code.

- Install TPA Screed to achieve appropriate falls to waste. Where a bonded screed is required, apply a bond coat using TPA 401M or TPA Lite.

If an engineered, rapid screed is needed, install TPA Rapid Screed, with a bond coat of TPA Rapid for bonded screeds.

TPA Screed is a pre-blended screed mixture for the installation of cementitious screeds and tile beds, suitable for internal and external floor applications.

TPA Rapid Screed is a pre-blended, rapid set, engineered screed mixture for the installation of cementitious screeds and tile beds, suitable for internal and external floor applications.

TPA 401M is a white, flexible, powdered adhesive for wall and floor applications.

TPA Lite is a premium grade, white, fibre-reinforced, flexible cement-based tile adhesive, based on a lightweight formulation.

TPA Rapid is a high-quality, cost-effective, rapid-setting, polymer-modified, grey cement-based tile adhesive.

- Install an appropriate fillet (bond breaker) to all transitions using WPA FC.

WPA FC is a high-performance, fast-cure, one-component polyurethane sealant.

- Install a puddle flange to all waste pipes ensuring that puddle flanges are recessed into the substrate.

- Apply WPA SB primer to non-porous surfaces such as puddle flanges and PVC pipes using the 2-cloth method. (The 2-cloth method is carried out as follows: dampen a clean cloth with an appropriate amount of WPA SB primer, and wipe evenly over the non-porous substrate utilizing a rubbing action. With a clean dry cloth, immediately remove all primer residues by implementing a buffing action).

WPA SB is a fast-drying, solvent-based primer, with exceptional penetrating properties. WPA SB primer is designed to assist in improving adhesion on porous and non-porous substrates.

- Apply WPA 460 or WPA 560 primer to the substrate being waterproofed.

WPA 460 is a two-part, water-based epoxy primer, used to seal concrete and masonry surfaces.

WPA 560 is a two-part, water-based epoxy primer, designed as a water and vapour-proof coating under waterproofing membranes.

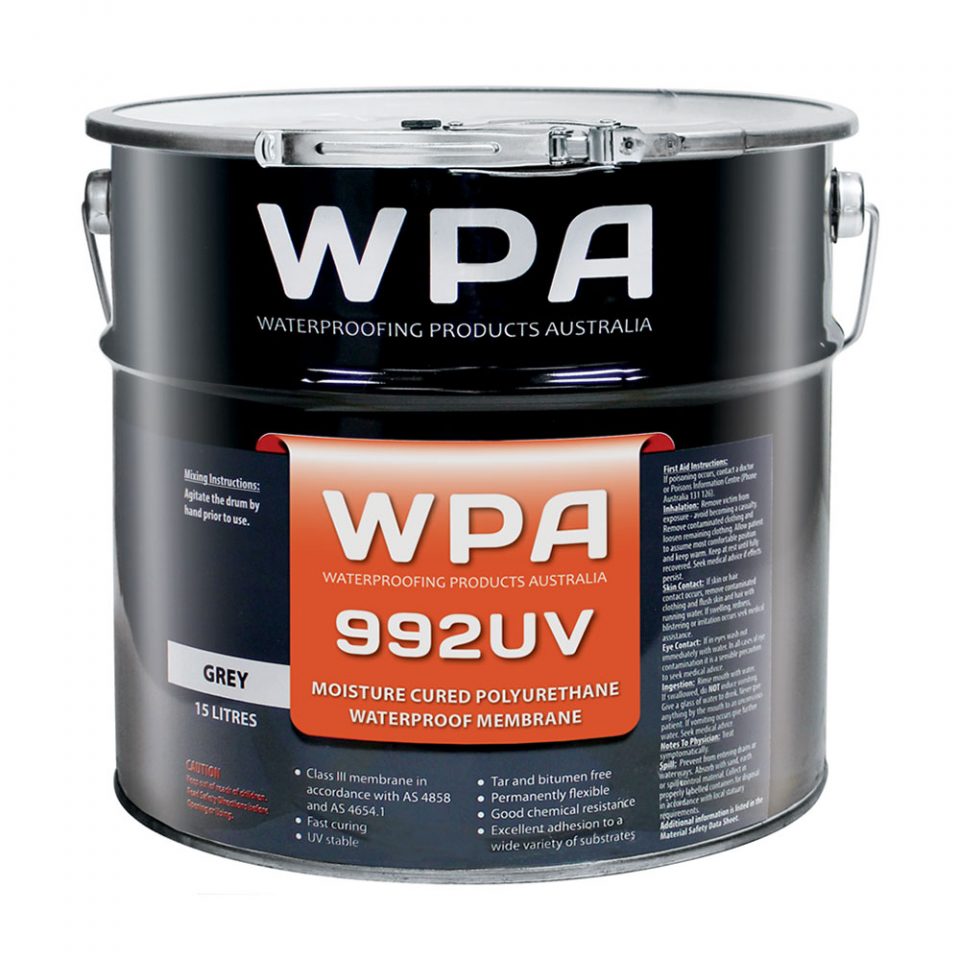

- Apply WPA 992UV membrane in a minimum of two coats to achieve the required dry film thickness. Ensure that the previous coat has completely dried before applying the subsequent coat(s). NOTE: All penetrations must be waterproofed.

NOTE: Surface finishes such as render, tiles and paint are highly unlikely to bond to WPA 992UV. If bonding of surface finishes to the waterproofing membrane is required, this area should be waterproofed with WPA 230UV (overlapped under WPA 992UV).

WPA 992UV is a thixotropic, one-part, liquid-applied, moisture-cured polyurethane waterproofing membrane, suitable for waterproofing most applications.

WPA 230UV is an elastomeric, fibre-reinforced, water-based polyurethane membrane system designed for exposed or under-tile applications.

- Apply WPA ATC top coat to the required dry film thickness, covering where WPA 992UV has been applied.

WPA ATC is an economical, aliphatic, single component, liquid applied, moisture cured, polyurethane coating, and offers protection from degradation of the waterproofing membrane due to UV exposure.

- Completely encapsulate parapet walls with primer and membrane. OPTIONAL: Cover membrane on parapet walls with metal capping, ensuring that capping is fixed on vertical surfaces only.

- Install over-flashing to cover membrane termination along walls. Leave a minimum 10mm gap from the finished floor level.

Products Used

- TPA Screed

- TPA 401M

- TPA Lite

- TPA Rapid Screed

- TPA Rapid

- WPA FC

- WPA SB

- WPA 460

- WPA 560

- WPA 992UV

- WPA 230UV

- WPA ATC