Systems

Miscellaneous

Home Bayset Systems Miscellaneous Systems Waterproofing Cracks and Control Joints – 805

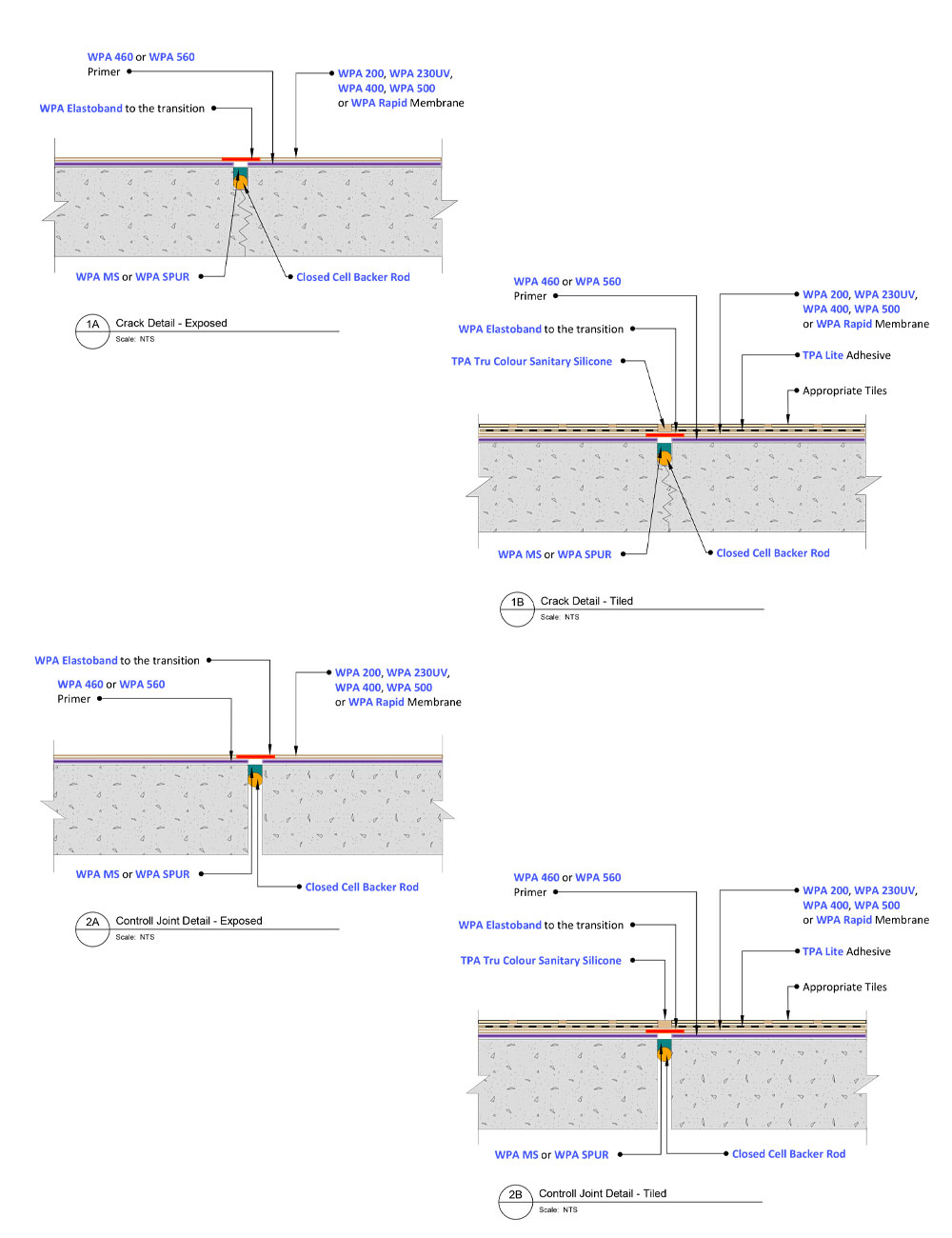

WP805 Waterproofing – Cracks and Control Joints

Preparation:

- All surfaces to be waterproofed must be firm, clean, dry, sound and smooth. All grease, oil, wax, curing compounds, loose material, paint and any other contaminants must be removed, masonry surfaces must be pointed flush and surface defects repaired. New concrete must be cured for a minimum of 28 days.

Installation:

- Waterproofing installation shall be in accordance with AS 3740 Waterproofing of Domestic Wet Areas or AS 4654.2 Waterproofing Membranes for External Above-Ground Use.

Tiling installation shall be in accordance with AS 3958.1 Ceramic Tiles – Guide to the Installation of Ceramic Tiles. - Square cut the crack or the control joint to a minimum depth of 15mm and width of 10mm. NOTE: Sealants require straight sides to adhere properly, do not V cut.

- Install a Closed Cell Backer Rod and cover with WPA MS or WPA SPUR.

Closed Cell Backer Rod is a compressible, closed-cell polyolefin foam tube with an outer skin. It is used as a backing for cold-applied sealants in expansion/construction joints and building seal applications.

WPA MS is a single-component, moisture-cured silane-modified hybrid sealant.

WPA SPUR is a high-quality, professional, universal, low-modulus sealant based on hybrid technology.

- Apply WPA 460 or WPA 560 primer to the substrate being waterproofed.

WPA 460 is a two-part, water-based epoxy primer, used to seal concrete and masonry surfaces.

WPA 560 is a two-part, water-based epoxy primer, designed as a water and vapour-proof coating under waterproofing membranes.

- Apply WPA 200, WPA 230UV, WPA 400, WPA 500 or WPA Rapid membrane in a minimum of two coats to achieve the required dry film thickness. Ensure that the previous coat has completely dried before applying the subsequent coat(s).NOTE: All penetrations must be waterproofed.

WPA 200 is a flexible, two-part, rapid-drying, cementitious waterproofing membrane system, specifically designed for use under tile, stone and exposed applications.

WPA 230UV is an elastomeric, fibre-reinforced, water-based polyurethane membrane system designed for exposed or under-tile applications.

WPA 400 is an elastomeric, fibre-reinforced waterproofing membrane based on high-performance polymer technology designed for use under tile finishes.

WPA 500 is a waterborne, fibre-reinforced, flexible waterproof membrane designed for use under tile finishes.

WPA Rapid is a fast-curing, waterborne flexible waterproof membrane designed for use under tile finishes.

- All transitions must be detailed utilising WPA Elastoband. Ensure WPA Elastoband is centred over the crack or the control joint.

WPA Elastoband is an innovative detailing system designed for waterproofing and sealing all types of joints, junctions and transitions subjected to movement.

- If tiling is required, continue with the following steps.

- Install tiles using TPA 401M, TPA 501R or TPA Lite tile adhesive.

TPA 401M is a white, flexible, powdered adhesive for wall and floor applications.

TPA 501R is a cost-effective, high-coverage, flexible, powdered adhesive for wall and floor applications.

TPA Lite is a premium grade, white, fibre-reinforced, flexible cement-based tile adhesive, based on a lightweight formulation.

- Grout tiles using TPA Tru Colour Grout or an approved alternative.

TPA Tru Colour Grout is a high-performance stain & efflorescence resistant grout. It is designed for use with most types of Ceramic, Mosaic, Natural Stone and Glass Tiles.

- Install backing rod to all perimeter and intermediate movement joints and seal with TPA Tru Colour Sanitary Silicone or an approved alternative.

TPA Tru Colour Sanitary Silicone is a mould-resistant, non-diluted, high-performance, UV-resistant, neutral cure silicone sealant.

Products Used

- Closed Cell Backer Rod

- WPA MS

- WPA SPUR

- WPA 460

- WPA 560

- WPA 230UV

- WPA 200

- WPA 400

- WPA 500

- WPA Rapid

- WPA Elastoband

- TPA 401M

- TPA 501R

- TPA Lite

- TPA Tru Colour Grout

- TPA Tru Colour Sanitary Silicone

800-105

WPA MS

800-106

WPA SPUR

490-005

WPA 460

490-134

WPA 560

425-023

WPA 230UV

750-110

Closed Cell Backer Rod

420-200

WPA 200

419-150

WPA 400

419-154

WPA 500

419-153

WPA Rapid

301-310

WPA Elastoband

105-751

TPA 401M

105-752

TPA 501R

105-755

TPA Lite

701-490

TPA TRU Colour Sanitary Silicone

104-351