Systems

Flooring

Home Bayset Systems Flooring Systems Sheet Vinyl Systems Floorcoverings – LVT, Vinyl Tiles – 711

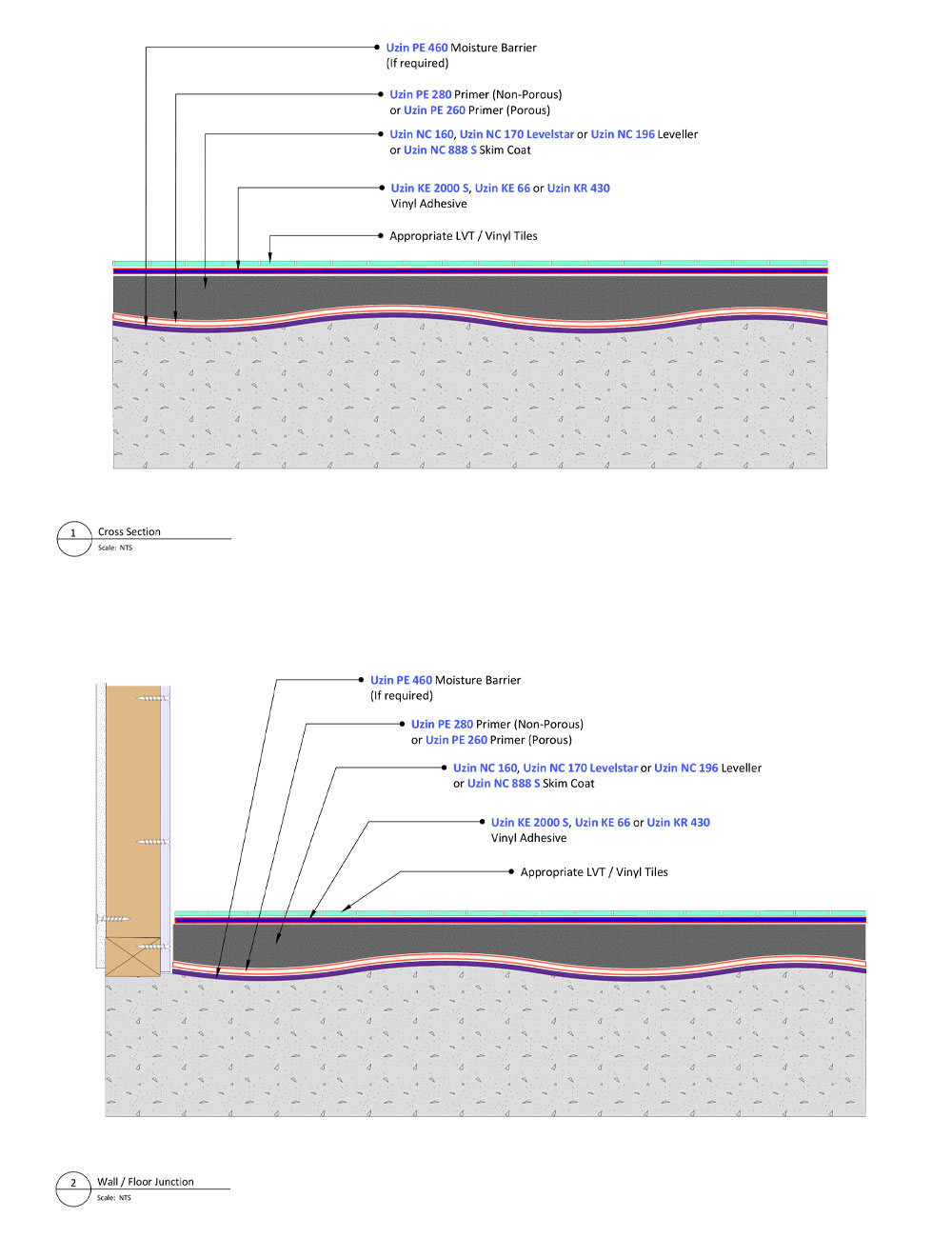

FL711 Floorcoverings – LVT / Vinyl Tiles

Preparation:

- Substrates must be firm, clean, dry, and sound. Substrates and subfloors must be free of grease, oil, wax, curing compounds, high levels of moisture (hydrostatic pressure), loose material, paint and any other contaminants. New concrete must be cured for a minimum of 28 days.

- Thoroughly vacuum loose material and dust.

- If mechanical preparation is required, prepare the floor using recommended methods as advised by substrate manufacturer.

- For concrete floors, moisture content and relative humidity tests should be conducted prior to installation.

Installation:

- Vinyl installation shall be in accordance with AS 1884 Floor Coverings – Resilient Sheet and Tiles – Installation Practices.

- Apply Uzin PE 460 epoxy moisture barrier if the relative humidity test shows moisture above 80%, or hydrostatic pressure / rising dampness is present or of concern.

Uzin PE 460 is an epoxy damp-proof membrane with low odour, mainly used as a moisture barrier up to 98% R.H. on cementitious screeds or concrete, for interior and exterior use.

- Apply Uzin PE 280 fast-drying primer on all non-porous substrates, including over Uzin PE 460 once dry.

Uzin PE 280 is a super-fast, film-forming primer, for use on dense and smooth internal substrates.

- Apply Uzin PE 260 on all porous substrates.

Uzin PE 260 is a dispersion-based primer that can be diluted. For use on dense and absorbent substrates, mainly for subsequent installation of smoothing compounds.

- Where required on uneven surfaces, install Uzin NC 160, Uzin NC 170 Levelstar or Uzin NC 196 on primed area/s, depending on depth requirement and/or curing time constraints.

Uzin NC 160 is a self-soothing compound for all types of floor coverings as well as wood flooring for thicknesses from 0 to 20 mm.

Uzin NC 170 Levelstar is an extremely smooth and quick-setting cementitious smoothing compound with excellent flow properties.

Uzin NC 196 is a fibre-reinforced smoothing compound for thicknesses from 3 to 40mm.

- Install Uzin NC 182 NEW repair mortar, where additional ramping is required.

Uzin NC 182 NEW is a moisture-resistant, low-slump and rapid internal repair mortar with reActivate effect for any range of thickness.

- If any additional smoothing is required, apply Uzin NC 888 S to primed surfaces.

Uzin NC 888 S is an ideal material for repairing minor imperfections, holes, trowel marks, skim coating and ramping. It can be applied by trowel from a true feather edge up to 4 mm depth in a single application.

- Once the levelling compound has cured, apply a layer of Uzin KE 2000 S, Uzin KE 66 or Uzin KR 430 with a notched trowel. Ensure to apply only the amount of adhesive that can be covered within the open time.

Uzin KE 2000 S is a strong dispersion adhesive with a short waiting time and long working time. It can be used as a wet-set adhesive. For use on internal floors and walls.

Uzin KE 66 is an LVT and Vinyl Tile-specific adhesive with high-shear resistance and is fibre-reinforced to reduce the formation of pressure marks in the floor covering.

Uzin KR 430 is a two-part polyurethane adhesive for all resilient flooring types, with extremely high final strength and for use in areas of extremely high traffic.

- Install the LVT or vinyl tiles into a wet film of adhesive and dry roll with a suitable heavy roller over the top of the LVT or vinyl tiles in a cross-hatch motion to ensure sufficient transfer of adhesive onto the backing.

Products Used

- Uzin PE 460

- Uzin PE 280

- Uzin NC 160

- Uzin NC 170

- Uzin PE 196

- Uzin PE 182

- Uzin NC 888

- Uzin KE 2000 S

- Uzin KE 66

- Uzin KR 430