Systems

Below Ground

Home Bayset Systems Below Ground Systems Retaining Walls with Negative Application Waterproofing Retaining Walls – Negative Application (Moisture Barrier) – 131

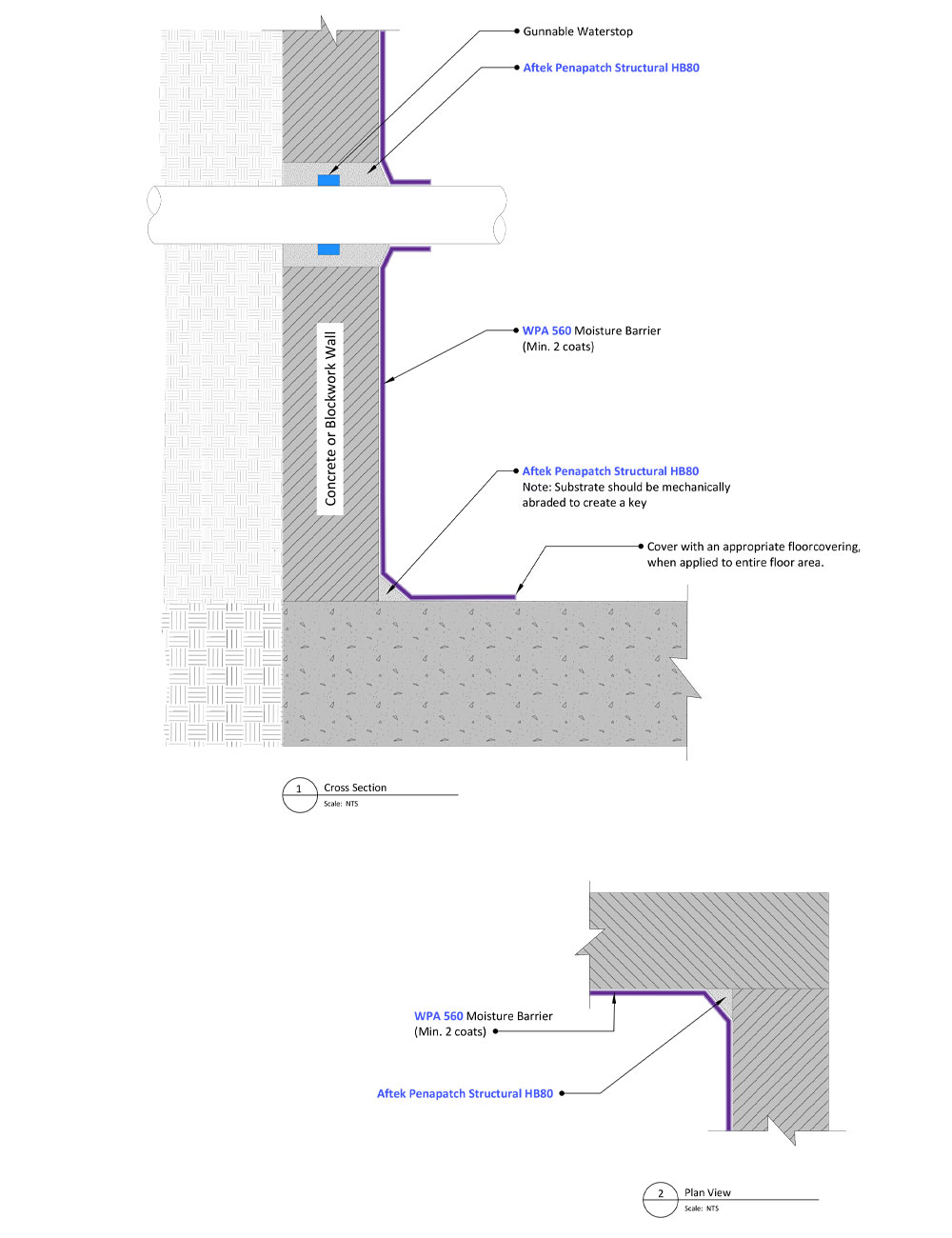

WP131 Waterproofing Retaining Walls – Negative Application (Moisture Barrier)

Preparation:

- All surfaces to be waterproofed must be firm, clean, dry, sound and smooth. All grease, oil, wax, curing compounds, loose material, paint and any other contaminants must be removed, masonry surfaces must be pointed flush and surface defects repaired. New concrete must be cured for a minimum of 28 days.

- External corners to be waterproofed must be bevelled to ensure a smooth transition of membrane from vertical to horizontal surfaces.

Installation:

- If the area to be waterproofed is subject to continuous water seepage, seal off the flow using WPA Plug.

WPA Plug is a high-strength instant solution for fixing leaks in structures even when water is actively flowing or under pressure. It provides excellent workability of approximately 40-60 seconds and is waterproof immediately.

- Repair all surface defects in concrete footing with Aftek Penapatch Structural HB80.

Aftek Penapatch Structural HB80 is a high strength; high build shrinkage compensated structural repair mortar.

- Install an appropriate cove to all vertical and horizontal internal corners using Aftek Penapatch Structural HB80.

- Install a Gunnable Waterstop around all penetrations. The waterstop must be packed in between at least a 50mm cover of Aftek Penapatch Structural HB80. Gunnable waterstop products are caulk-grade, single-component swelling pastes used to stop water infiltration through concrete construction joints.

- Install two coats of WPA 560 membrane to achieve a minimum 0.3mm dry film thickness. Ensure that the previous coat has completely dried before applying the subsequent coat(s). NOTE: All penetrations must be waterproofed. Note: WPA 560 is not designed as a trafficable coating and must be covered with an appropriate floorcovering, when applied to the entire floor area.

Products Used

- WPA Plug

- Aftek Penapatch Structural HB80

- WPA 560