Systems

Below Ground

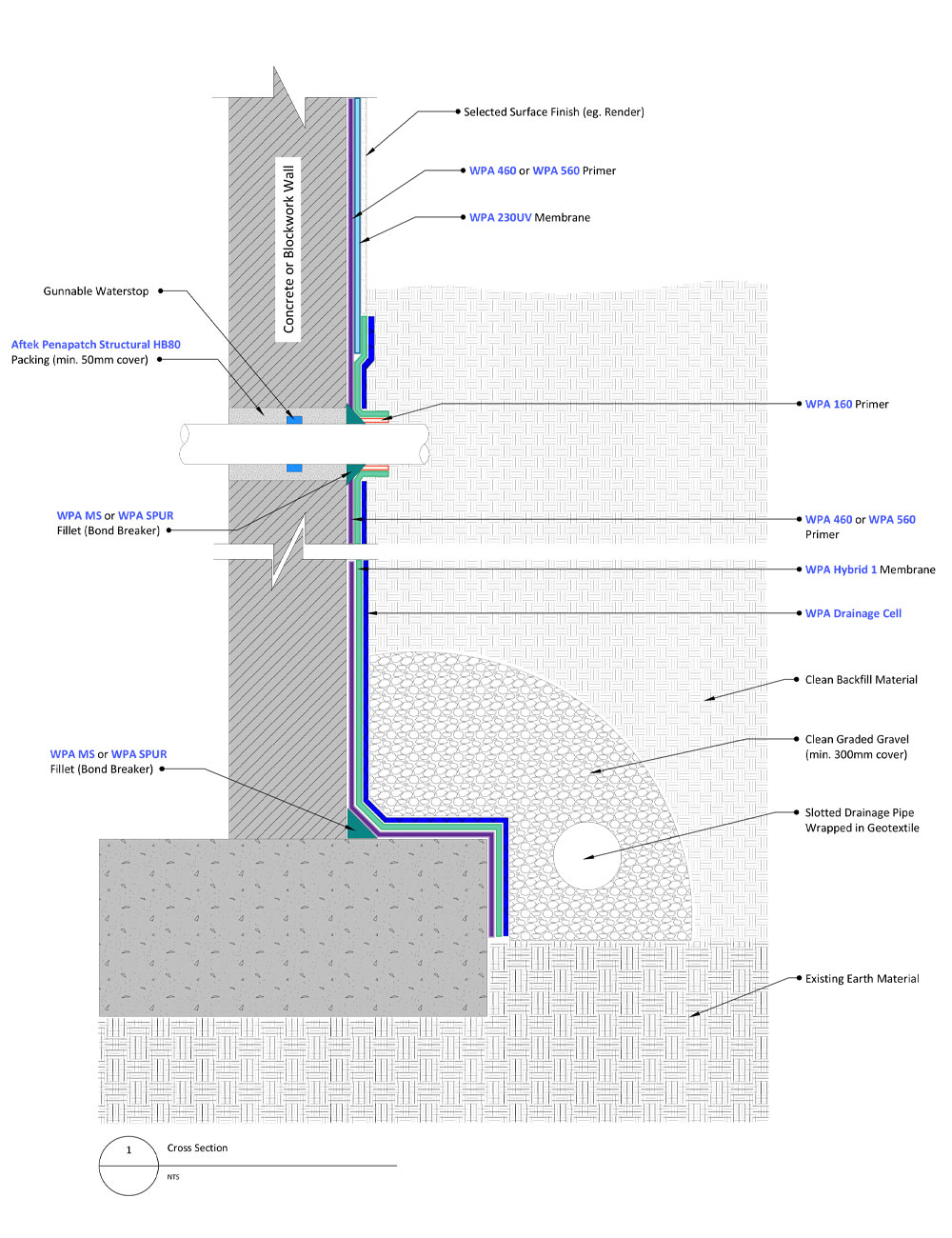

Home Bayset Systems Below Ground Systems Retaining Walls on Strip Footings Liquid Membrane Retaining Walls on Strip Footing – 113

WP113 Waterproofing – Retaining Walls on Strip Footing

Preparation:

- All surfaces to be waterproofed must be firm, clean, dry, sound and smooth. All grease, oil, wax, curing compounds, loose material, paint and any other contaminants must be removed, masonry surfaces must be pointed flush and surface defects repaired. New concrete must be cured for a minimum of 28 days.

- External corners to be waterproofed must be bevelled to ensure a smooth transition of membrane from vertical to horizontal surfaces.

Installation:

- Repair all surface defects on retaining wall masonry surfaces with Aftek Penapatch Structural HB80.

Aftek Penapatch Structural HB80 is a high strength; high build shrinkage compensated structural repair mortar.

- Install a Gunnable Waterstop around all penetrations. The waterstop must be packed in between at least a 50mm cover of Aftek Penapatch Structural HB80.

Gunnable Waterstop products are caulk-grade, single-component swelling pastes used to stop water infiltration through concrete construction joints.

- Install an appropriate fillet (bond breaker) to all transitions using WPA MS or WPA SPUR.

WPA MS is a single-component, moisture-cured, silane-modified hybrid sealant.

WPA SPUR is a high-quality, professional, universal, low-modulus sealant based on hybrid technology.

- Apply WPA 160 primer to non-porous surfaces, such as PVC and metal pipe penetrations.

WPA 160 is a specialised solvent-free primer designed for enhancing the adhesion of subsequent membranes, adhesives, toppings and decorative finishes over non-porous substrates.

- Apply WPA 460 or WPA 560 primer to the substrate being waterproofed.

WPA 460 is a two-part, water-based epoxy primer, used to seal concrete and masonry surfaces.

WPA 560 is a two-part, water-based epoxy primer, designed as a water and vapour-proof coating under waterproofing membranes.

- Apply WPA Hybrid 1 membrane to the external side and top of the retaining wall, ensuring that the first coat has completely dried before applying the second coat. NOTE: Where surface finishes such as render, tiles and paint are required, this area should be waterproofed with WPA 230UV and allowed to dry prior to overlapping with the WPA Hybrid 1.

WPA Hybrid 1 is a one-part, liquid-applied, moisture-cured non-hazardous waterproofing membrane based on SMP technology (Silyl Modified Polymer), which offers a safe alternative to solvent-based PU membranes.

WPA 230UV is an elastomeric, fibre-reinforced, water-based polyurethane membrane system designed for exposed or under-tile applications.

- Install WPA Drainage Cell on all waterproofed surfaces below ground level.

WPA Drainage Cell is a two-core drainage sheet consisting of a non-woven geotextile filter layer thermally welded to a water-impermeable, recycled HDPE (High-Density Polyethylene) drainage membrane.

- Install a slotted drainage pipe wrapped in geotextile next to the slab edge.

- Cover the drainage pipe with a minimum of 300mm of gravel and cover the gravel with an additional geotextile filter layer.

- Backfill with clean material.

Products Used

- Aftek Penapatch Structural HB80

- WPA MS

- WPA SPUR

- WPA 160

- WPA 460

- WPA 560

- WPA Hybrid 1

- WPA 230UV

- WPA Drainage Cell